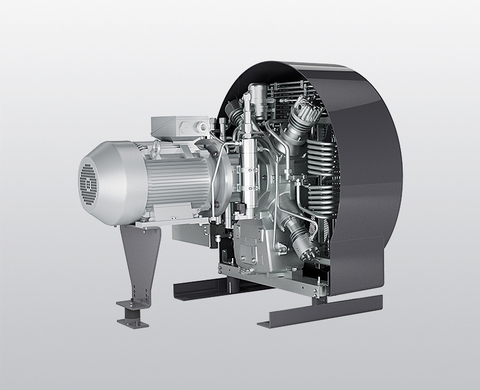

The GIB series: Air-cooled, high-pressure booster compressors for the compression of air and nitrogen – designed for the most demanding operating conditions

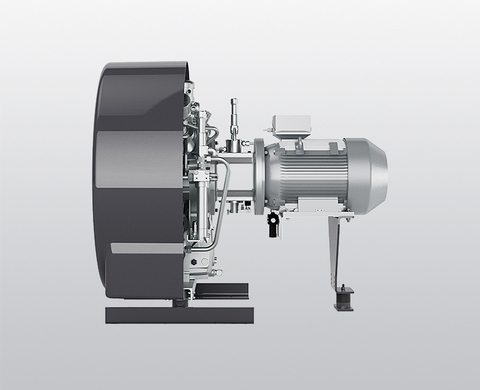

Air-cooled design with a large cooling fan: Provides optimal cooling across all cylinders even at high ambient temperatures

Compact dimensions: The space-saving, low-maintenance and reliable solution – even for limited spaces

Ergonomic design: optimum accessibility and operation

B-DRAIN: The new automatic condensate drain is quieter and saves energy

As cost-effective and durable system solutions, these multi-stage boosters offer a wide and varied range of options: as a booster compressor of air from a compressed air supply system or as a nitrogen compressor of inert gases from generators or storage bundles.

The new boosters of the K 22 series are offered in direct-coupled design. High efficiency, low operating costs and a low-maintenance design make them the first choice for demanding applications.

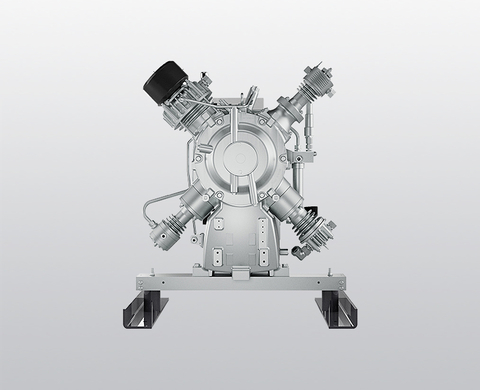

The star arrangement of the pistons and cylinders enables optimised mass balancing, which means that the units run with extremely low vibration.

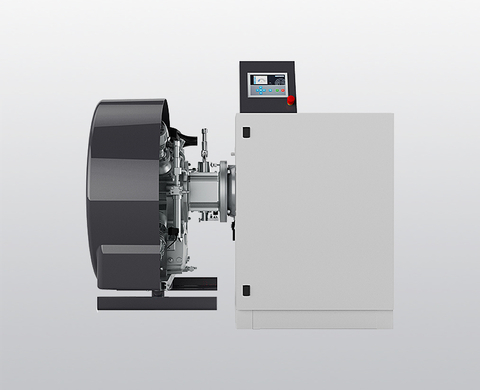

The compressor control can be flexibly placed next to the unit, which offers advantages during installation.

A powerful air cooling system with generously dimensioned coolers combined with cylinders with extensive ribbing can be relied upon for best possible cooling of each individual compressor stage.

In line with your individual needs and industrial requirements, BAUER KOMPRESSOREN can also provide you with tailor-made turnkey system solutions.

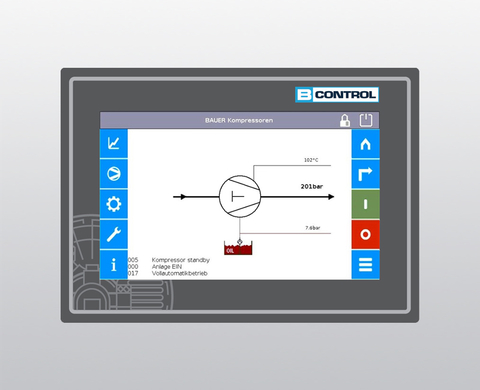

All the information you need at your fingertips!

B-CONTROL MICRO compressor control

The B-CONTROL MICRO is a modern, easy-to-use compressor control with colour display for the control and reliable monitoring of all basic functions. Read more

Compressor block

Depending on the model, the compressor blocks in the K 22 series feature 2 to 5 compressor stages for final pressure levels up to 525 bar. Read more

The system concept

The compressor units are equipped with vibration dampers and allow installation without foundations. Read more

B-CONTROL III

B-CONTROL III is BAUER's premium control system for demanding applications. Read More

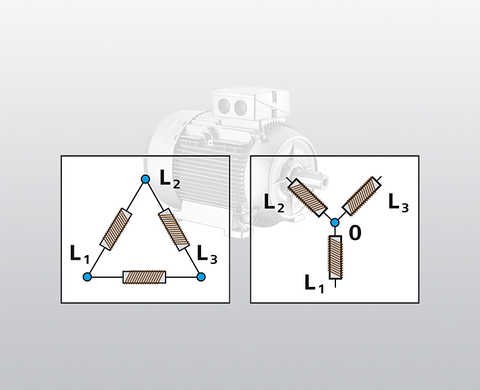

Start-up configuration

At and above motor power ratings of 75 kW and in conjunction with the B-CONTROL, a soft starter to protect the unit during starting and effectively reduce starting current is used as standard. The technical alternative is soft staring with a frequency inverter. Read more

Monitoring of pressure and temperature

This add-on module for the B-CONTROL control monitors the pressures and temperatures of all compressor stages. Read more

Intake pressure reduction

Intake pressure reduction ensures that the compressor takes in the gas at the appropriate pressure. Depending on the prevailing gas pressure and the intake pressure required, 1-stage or 2-stage intake pressure reducers are used. Integrated safety valves and pressure monitoring provide an effective means of ensuring that the permissible intake pressure is not exceeded or undershot.

Intake buffer vessel

To effectively prevent pulsations in the intake area, an intake buffer vessel is installed between the compressor and the upstream gas supply networks and/or control equipment. Read more

60-litre condensate vessel

The generous 60 l condensate collection system provides a central collection point for the condensate produced during the compression process inside the compressor. Read more

Condensate vessel (noble gases)

During the compression of helium and argon, the gas released with the condensate is fed into the condensate vessel. Read more

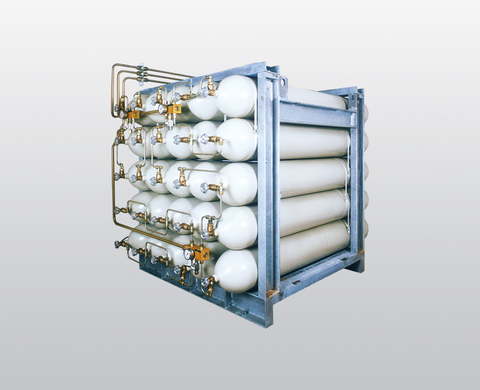

Storage systems

Modular high-pressure storage systems by BAUER KOMPRESSOREN are the ideal way to expand a compressor system. Read more

Scope of delivery, basic version

Complete compressor unit ready for operation. Read more

| Type designation | Effective free air delivery ¹ | Intake pressure | Shut-down pressure min. | max. ² | No. of compr. stages | Speed approx. | Motor output | Net weight approx. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| l/min | m³/h | cfm | bar | bar | bar | rpm | kW | kg | lbs | ||

GIB 22 booster series, 90 to 365 bar – 50 Hz | |||||||||||

| GIB 22.10-30 | 930 | 55.8 | 32.8 | 2 | 90 | 250 | 4 | 1480 | 30 | 780 | 1720 |

| 1250 | 75 | 44.1 | 3 | 150 | 300 | ||||||

| 1550 | 93 | 54.7 | 4 | 160 | 350 | ||||||

| 1700 | 102 | 60 | 4.5 | 160 | 350 | ||||||

| GIB 22.12-37 | 1250 | 75 | 44.1 | 4.5 | 120 | 300 | 4 | 1480 | 37 | 830 | 1830 |

| 1600 | 96 | 56.5 | 6 | 150 | 350 | ||||||

| 2050 | 123 | 72.4 | 8 | 230 | 350 | ||||||

| 2500 | 150 | 88.3 | 0 | 230 | 350 | ||||||

| Type designation | Effective free air delivery ¹ | Intake pressure | Shut-down pressure min. | max. ² | No. of compr. stages | Speed approx. | Motor output | Net weight approx. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| l/min | m³/h | cfm | bar | bar | bar | rpm | kW | kg | lbs | ||

GIB 22 booster series, 90 to 365 bar – 60 Hz | |||||||||||

| GIB 22.10-37 | 1100 | 66 | 38.8 | 2 | 90 | 250 | 4 | 1770 | 37 | 830 | 1830 |

| 1480 | 88.8 | 52.3 | 3 | 150 | 300 | ||||||

| 1850 | 111 | 65.3 | 4 | 160 | 350 | ||||||

| 2050 | 123 | 72.4 | 4.5 | 160 | 350 | ||||||

| GIB 22.12-37 | 1500 | 90 | 53 | 4.5 | 120 | 300 | 4 | 1770 | 37 | 830 | 1830 |

| 1900 | 114 | 67.1 | 6 | 150 | 350 | ||||||

| 2450 | 147 | 86.5 | 8 | 230 | 350 | ||||||

| 3000 | 180 | 105.9 | 10 | 230 | 350 | ||||||

¹ Free air delivery according to ISO 1217, valid for air and nitrogen. Availability and values for helium, argon and other gases on request.

² Shut-down pressure (sensor setting)

Downloads for BAUER air-cooled boosters

BAUER Compressors for Industry – Tailored to your requirements