I 22 – The professional stationary compressor units with electric drive for the most demanding application conditions

Tailored to meet the needs of your application

Very easy to maintain: Thanks to proven BAUER system components

Fully automatic compressor control: B-CONTROL MICRO

Little space required: Thanks to compact horizontal design

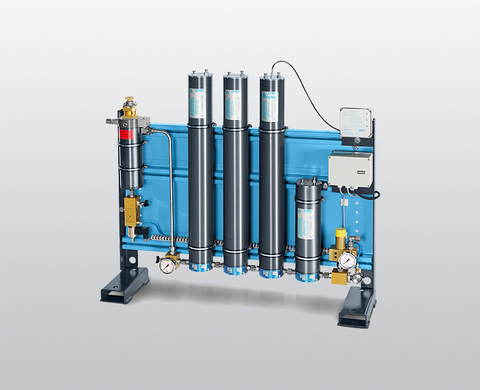

External P 80/P 100 filter system: Providing you with clean breathing air conforming to DIN EN 12021¹, the standard for breathing air

The I 22 series by BAUER KOMPRESSOREN is tailor-made to deliver high performance in professional applications under the toughest conditions.

Outstanding ease of maintenance is just as much a matter of course for us as the wide range of possible applications - optimally matched to your specific needs.

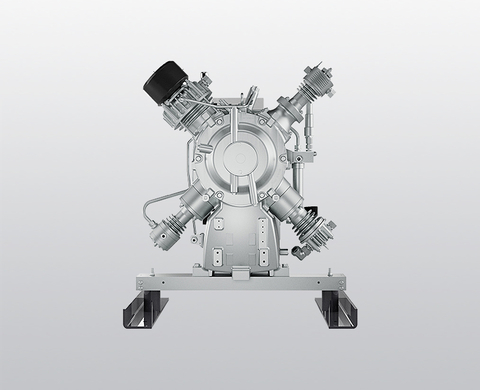

Your IK 22 series compressor block has been designed for the most demanding professional applications. Dimensioned for more than 30,000 operating hours, it has proven its worth in thousands of application scenarios.

With their outstanding surface hardness, plasma-nitrided and plateau-honed cylinders are able to achieve extremely long service lives combined with low energy consumption and reliable oil lubrication of cylinder surfaces.

Furthermore, wear-resistant piston rings in the final stage minimize running costs. The compressor block is both efficient and reliable. Stainless steel cooling ribs provide the basis for particularly efficient cooling and thus very long service life. The units of the new K 22 series are designed with direct coupling.

¹ If the units are maintained and installed correctly as described in the user manual and subject to the BAUER AERO-GUARD being used if CO2 concentration in the intake air exceeds prescribed standard values.

All the information you need at your fingertips!

K 22 compressor block

The BAUER K 22 series compressor block has been designed for the most demanding professional applications. Dimensioned for more than 30,000 operating hours, it has proven its worth in thousands of application scenarios. Read more

P 80 or P 100 filter system

When used in conjunction with original BAUER filter cartridges, the P 80 or P 100 filter systems with oil and water separator and pressure retention check valve can be relied upon for breathing air treatment conforming to DIN EN 12021¹. A type-tested and sealed final pressure safety valve enables particularly high levels of operational safety to be achieved. 5200 m³ (P 80) or 8000 m³ (P 100) of air can be treated.

¹ If the units are maintained and installed correctly as described in the user manual and subject to the BAUER AERO-GUARD being used if CO2 concentration in the intake air exceeds prescribed standard values.

B-CONTROL MICRO compressor control

The B-CONTROL MICRO is a modern, easy-to-use compressor control with colour display for the control and reliable monitoring of all basic functions. Read more

B-SECURUS filter monitoring

The B-SECURUS system monitors the saturation of the filter cartridge(s) by measuring the moisture in the molecular sieve. Read more

Paint finish/Special paint finish

All frame parts of BAUER compressors are finished with a sophisticated powder coating. Read more

AERO-GUARD

Using the AERO-GUARD reduces the CO2 content of the breathing air to approximately one-third of the intake value. The constantly increasing levels of CO2 concentration in the air resulting from unfavourable environmental influences are making it more and more difficult for the operators of filling stations to be sure of achieving compliance with legally binding maximum limits for CO2. With AERO-GUARD the operator is always on the safe side! Read more

60 l condensate collection system

This convenient system provides a central collection point for the condensate (oil and water mixture) produced during the compression process inside the compressor. The condensate tank features an integrated float switch which can be relied upon to monitor the level of condensate in the tank and provides protection against overfilling. A combined silencer and filter unit prevents pollution caused by noise or odour.

Scope of delivery, basic version

Complete compressor unit ready for operation. Read more

I 22 breathing air compressor, 90 – 450 bar, 870 – 1300 l/min: With electric motor

| Type designation | Effective free air delivery ¹ | Max. operating pressure ² | Number of compr. stages | Speed approx. | Motor output | ||

|---|---|---|---|---|---|---|---|

| l/min | cfm | bar | psig | rpm | kW | ||

330 bar | |||||||

| I22.0-22 | 900 | 31.8 | 350 | 5300 | 4 | 985 | 22 |

| I22.0-30 | 1300 | 45.9 | 350 | 5300 | 4 | 1485 | 30 |

450 bar | |||||||

| I22.0-22 | 900 | 31.8 | 450 | 6525 | 4 | 985 | 22 |

| I22.0-37 | 1300 | 54.9 | 450 | 6525 | 4 | 1485 | 37 |

| Type designation | Effective free air delivery ¹ | Max. operating pressure ² | Number of compr. stages | Speed approx. | Motor output | ||

|---|---|---|---|---|---|---|---|

| l/min | cfm | bar | psig | rpm | kW | ||

90 – 450 bar | |||||||

| I22.2-22 | 870 | 30.7 | 450 | 6525 | 4 | 1.180 | 22 |

| I22.2-37 | 1300 | 45.2 | 450 | 6525 | 4 | 1.770 | 37 |

¹ Free air delivery according to ISO 1217, power consumption at maximum final pressure under certain conditions. Other ambient conditions result in different performance data.

² Max. operating pressure = max. safety valve pressure setting; reduced switch-off pressure.

Downloads for KAP 220 & KAP 23, compressor and compressor accessories

BAUER PREMIUM LINE – Compressors for sports & safety applications

Product overview – Compressor systems & accessories for medium and pressure