PE-MVE – the space-saving stationary breathing air compressor which ensures quiet operation at an attractive price!

Super-Silent cladding as standard: With low noise level for use in working environments where noise is a key concern

Fully automatic, easy-to-use compressor control: BHW CONTROL

Integrated filling device: 2 non-kinking filling hoses in the standard scope of supply

Compact dimensions: for installation wherever space is at a premium

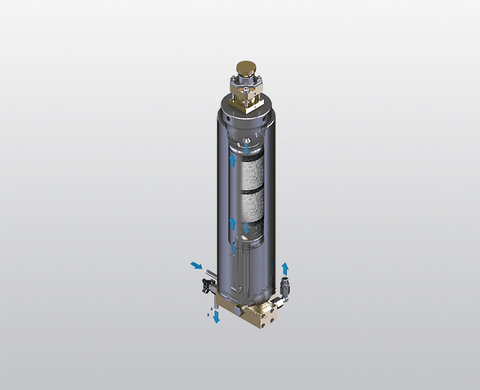

The PE-MVE from BAUER is the compact complete solution in a vertical format for all applications requiring medium delivery rates. Equipped with noise insulation housing as standard, the PE-MVE is ideal for use in environments where noise is a key concern and for customers who need reliable and durable service combined with low running costs.

What's more, the high-pressure compressors are already equipped with an automatic condensate drain and easy-to-use BHW CONTROL, which has a fully automatic mode for filling storage bottles.

All the information you need at your fingertips!

IK 120 compressor block

The BAUER IK 120 series compressor block has been designed for the most demanding professional applications. Dimensioned for more than 30,000 operating hours, it has proven its worth in thousands of application scenarios. Read more

Super-Silent version

The Super-Silent cladding, which is installed as standard, impresses with its low noise level for working environments in which noise is a key concern and flexible installation options.

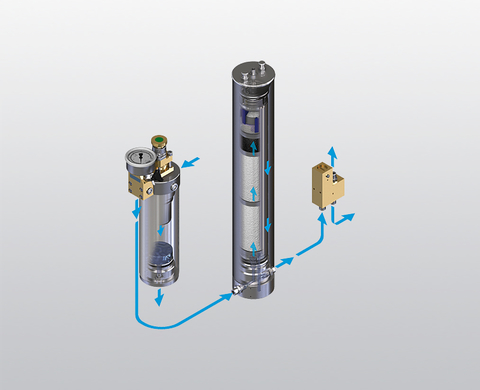

P 31 filter system

When used in conjunction with original BAUER filter cartridges, the P 31 filter system with integrated oil and water separator and pressure retention check valve can be relied upon for breathing air treatment conforming to DIN EN 12021¹. A type-tested and sealed final pressure safety valve enables particularly high levels of operational safety to be achieved. 600 m³ of air can be treated.

¹ If the units are maintained and installed correctly as described in the operating instructions or user manual and if the concentration of CO2 in the intake air does not exceed the values specified in the applicable standard for breathing air.

B-DRAIN automatic condensate drain

The automatic condensate drain automatically removes the condensate that forms during compression (water/oil mixture) from the intermediate separators and the final separator and collects it in a condensate vessel. Read more

Filling hose

High-quality UNIMAM high-pressure filling hoses made from food-safe and long-life hose material make for flexible and safe handling. Swivel hose connections enable the filling valve to be connected to the breathing air cylinder quickly, easily and safely.

B-TIMER filter cartridge monitoring

The operating hours and the current level of cartridge saturation are displayed on the unique B-TIMER mini-computer. Read more

SECURUS is a direct asset to your safety!

SECURUS is an electronic filter cartridge saturation control which continuously monitors the ability of the final filter cartridge to dry breathing air in accordance with the standard EN 12021:2014. Read more

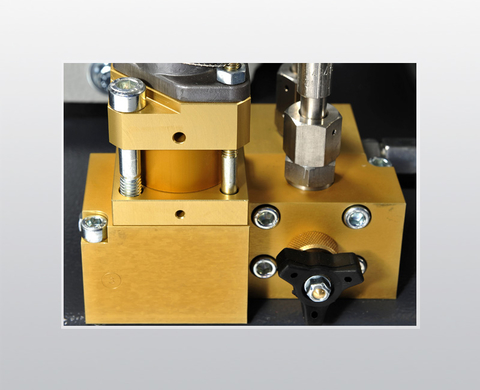

Switch-over device

The optional equipment with a switch-over device makes switching from 200 to 300 bar and vice versa easy and flexible. Read more

P 41 Purification system

When used in conjunction with original BAUER filter cartridges, the P 41 filter system with additional oil and water separator and pressure retention check valve can be relied upon for breathing air treatment conforming to DIN EN 12021:2014¹. A type-tested and sealed final pressure safety valve enables particularly high levels of operational safety to be achieved. 1550 m³ of air can be treated.

¹ If the units are maintained and installed correctly as described in the user manual and subject to the BAUER AERO-GUARD being used if CO2 concentration in the intake air exceeds prescribed standard values.

Fully automatic compressor control

The compressor control is also available in a fully automatic version. As well as switching off automatically when the final pressure is reached, the compressor also restarts by itself as soon as the pressure falls below a specified minimum value. Ideal for use in storage mode.

Integrated gas measurement system B-DETECTION PLUS i

As an option, the B-DETECTION PLUS i gas measurement system can be integrated into the compressor. This permits the monitoring of all gases required by DIN EN 12021:2014. Thanks to the option for discharge to the outside in the event of short-term contamination and the shut-down of the compressor in the event of extended overruns of the limit values, observance of DIN EN 12021:2014 can be ensured at all times1.

1 Measurement of humidity and total oil value (VOC) as option. Total oil measurement based only on volatile organic compounds (VOCs). Sensor calibration based on isobutene.

Intermediate pressure gauge kit

The intermediate pressure gauges show the operating pressure of the individual compressor stages. This information about the pressure is used to check the corresponding stage valves (inlet and outlet) for leaks so that potential faults can be detected quickly. The intermediate pressure gauges are installed inside the compressor housing.

AERO-GUARD

Using the AERO-GUARD reduces the CO2 content of the breathing air to approximately one-third of the intake value. The constantly increasing levels of CO2 concentration in the air resulting from unfavourable environmental influences are making it more and more difficult for the operators of filling stations to be sure of achieving compliance with legally binding maximum limits for CO2. With AERO-GUARD the operator is always on the safe side! Read more

BAUER high-pressure storage

BAUER high-pressure storage system for optimum operation of the compressor unit. Recommended for high collection rates and the immediate availability of breathing air. Read more

Scope of delivery, basic version

Complete compressor unit ready for operation. Read more

| Type designation | Charging rate ¹ | Max. operating pressure | Filter system | Number of compressor stages | Speed approx. | Motor and power | Net weight | Dimensions L × W × H | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| l/min | cfm | bar | psig | rpm | Motor | kW | approx. kg | cm | |||

| PE 250-MVE | 250 | 9 | 350 | 4780 | P 31 | 3 | 1450 | Three-phase motor 400 V, 50 Hz ² | 5.5 | 250 | 104 × 75.5 × 132 |

| PE 300-MVE | 300 | 10 | 350 | 4780 | P 31 | 3 | 1800 | Three-phase motor 400 V, 50 Hz ² | 7.5 | 260 | 104 × 75.5 ×132 |

| PE 200/420-MVE | 200 | 7 | 420 | 6000 | P 41/420 | 3 | 1270 | Three-phase motor 400 V, 50 Hz ² | 5.5 | 270 | 104 × 75.5 ×132 |

| PE 250/420-MVE | 250 | 9 | 420 | 6000 | P 41/420 | 3 | 1470 | Three-phase motor 400 V, 50 Hz ² | 5.5 | 270 | 104 × 75.5 ×132 |

¹ Measured with cylinder filling (10 l) from 0 to 200 bar, ± 5%

² Connecting plug configuration: 16 A

Downloads for the PE-MVE breathing air compressor and compressor accessories

PE-MVE – Compressor for sports & safety applications

POSEIDON EDITON – Compressors for sports & safety applications