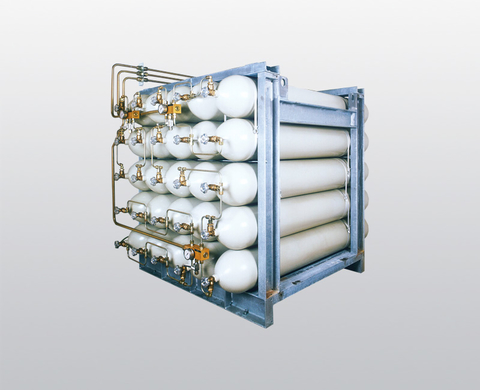

BAUER high-pressure storage systems – The essential components of your system

Modular system structure: The ideal way to expand your compressor system

Storage systems for a wide range of pressure stages: dimensioned for 330, 350 and 420 bar

Suitable for many media: air, nitrogen, inert gases and nitrox

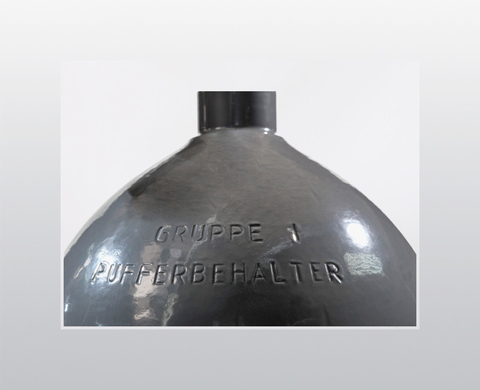

A correctly dimensioned (storage) vessel is one of the most important components of the entire system. It will reduce pressure fluctuations when large amounts of air are consumed and minimise the number of compressor on/off cycles by providing the correct storage capacity.

At the same time, a carefully selected storage module optimises compressor distribution during runtime and also serves as a pulsation damper.

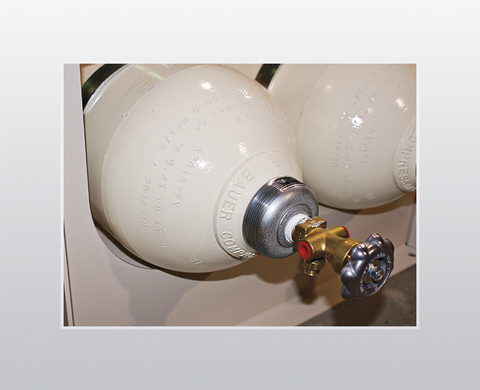

The storage systems are available in pressure stages of 330, 350 and 420 bar. They can be expanded as required by adding 50 or 80 l storage cyliniders.

All the information you need at your fingertips!

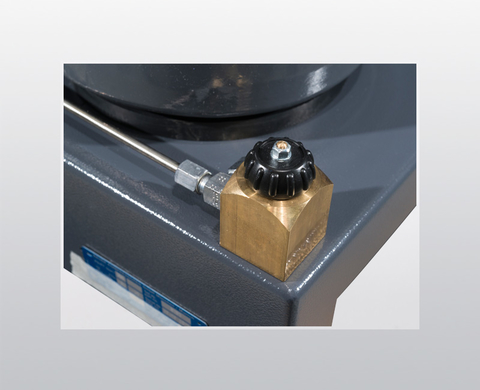

Safety valve and pressure gauge

Safety valve and pressure gauge are mounted on the console of the first module. This is essential if no other means of preventing the maximum permissible storage pressure from being exceeded is in place, e.g. approved safety valves on the compressor or in the supply line.

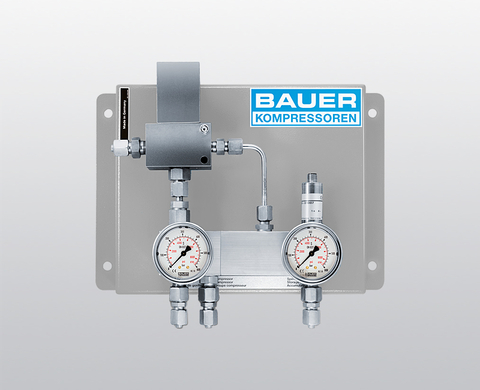

Automatic selector unit

An automatic selector unit supports fully automatic switch-over between BAUER high-pressure storage units and the compressor unit. Read more

Scope of delivery, basic version

Standard module, storage module horizontal (B 800 … B 3360). Read more

How do I select the size of the storage system correctly to limit the number of start/stop cycles and load cycles?

The following information answers this important question and will help you to find the right storage system for your requirements.

A correctly dimensioned (storage) vessel is one of the most important components of the entire system. It will reduce pressure fluctuations when large amounts of air are consumed and minimise the number of compressor on/off cycles by providing the correct storage capacity.

For high-pressure compressors, remember that the final separator in the compressor and the storage vessel are only dimensioned for a certain number of load cycles, i.e.: the fewer compressor switching cycles, the longer the service life of these components.

To optimise the performance of the unit and maximise the service life of the final separator based on the number of permissible load cycles, the operation of the compressor should be regulated so that there are no more than 2 - 4 ON cycles every hour.

For your safety, cycle counters are installed in BAUER industrial compressors as standard to record the number of cycles actually completed.

The size of the storage system is determined by:

- Free air delivery (l/min) of the compressor

- Air consumption of the application concerned

- Pressure difference between start and stop (hysteresis)

Simplified formula for the configuration of a high-pressure storage system based on 4 load cycles/hour:

V(l) | = | Vk × 4 |

| Vk (l/min) | = | Delivery rate of the compressor in litres per minute |

|---|---|---|

| V(l) | = | Storage volume in litres (water volume) |

| Δ p (bar) | = | Start/stop pressure difference (hysteresis) in bar |

We recommend a pressure difference Δ up to max. 60 bar. Up to this difference, stationary HP storage bottles are generally permitted for use in continuous operation. Above this level, the vessels are limited with regard to the number of filling cycles. Please refer to the information in the documentation supplied with the respective pressure vessel.

| Storage system | Operating pressure | Volume geometric | Number of vessels | ||

|---|---|---|---|---|---|

| 330 bar | 350 bar | 420 bar | Liter | ||

| B 50 | – |

|

| 50 | 1 |

| B 50 (Nitrox) | – |

| – | 50 | 1 |

| B 80 |

| – | – | 80 | 1 |

| Storage system | Number of cylinders | Total volume geometric | Operating pressure | Design | ||

|---|---|---|---|---|---|---|

| Litres | bar | 1-rack | 2-rack | 3-rack | ||

| B 800 | 10 | 800 | 330 |

|

|

|

| B 960 | 12 | 960 | 330 |

|

|

|

| B 1920 | 24 | 1920 | 330 |

|

|

|

| B 2400 | 30 | 2400 | 330 |

|

|

|

| B 3360 | 42 | 3360 | 330 |

|

|

|

Downloads for the high-pressure storage systems and compressor accessories

BAUER Accessory Systems – The ideal enhancement to your compressor