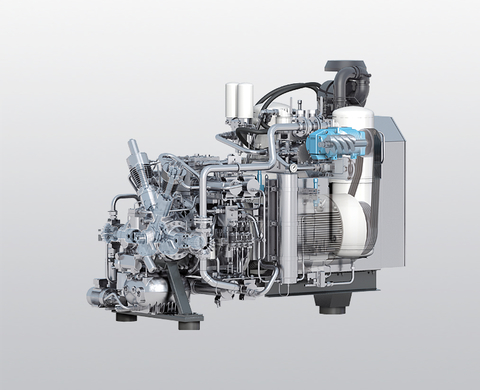

Water-cooled high-pressure compressors in the GIB-SP-series in the pressure range 50 – 520 bar – for heavy-duty operation in industrial applications

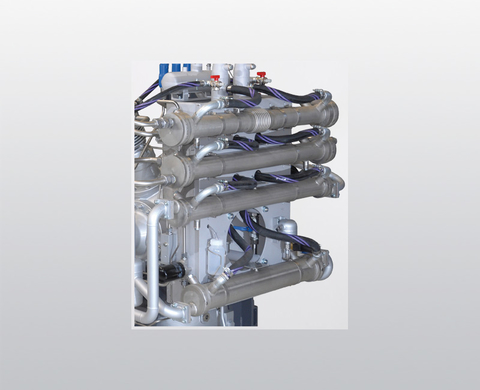

Cooling of valve heads reduces thermal load: For minimum wear

Installation even under the most difficult ambient conditions: Thanks to dedicated water cooling of the compressor block

Low compression temperatures and operating temperatures: thanks to a multi-stage compression process

Fully equipped: with soft starting and B-CONTROL II

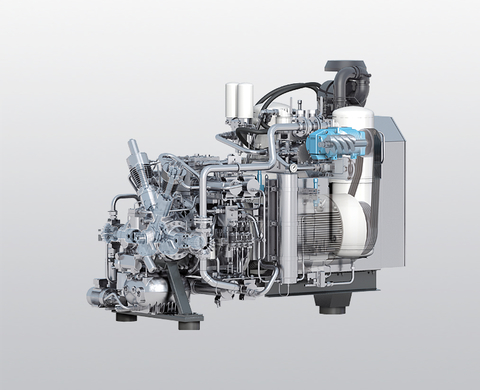

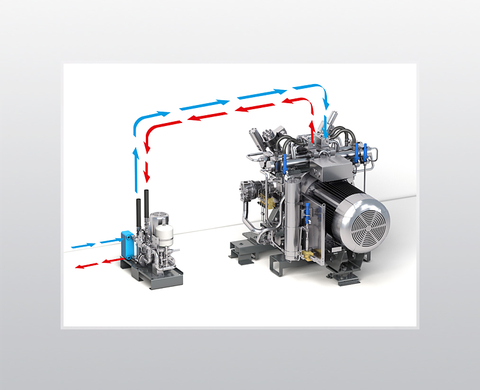

The combination of the screw compressor and high-pressure booster enables a high level of free air delivery with compact dimensions. The compression process involves 3 respectively 5 stages, keeping compression temperatures to a minimum.

By using targeted water cooling between the interstage and afterstage coolers and valve heads, the system enables the majority of the heat produced to be absorbed by the cooling water.

As a result, these industrial high-pressure compressors require very little maintenance and achieve long service lives. At the same time, they are quieter than comparable air-cooled compressors and designed specifically for continuous use in industrial applications (heavy-duty use).

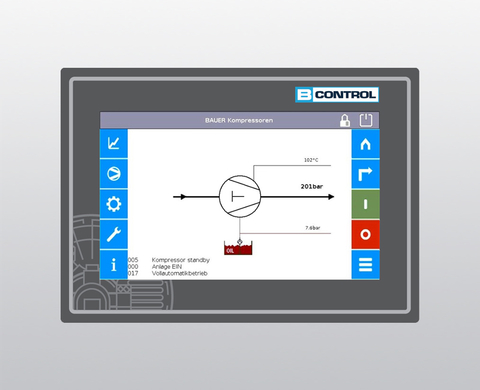

All the information you need at your fingertips!

B-CONTROL III

B-CONTROL III is BAUER's premium control system for demanding applications. Read More

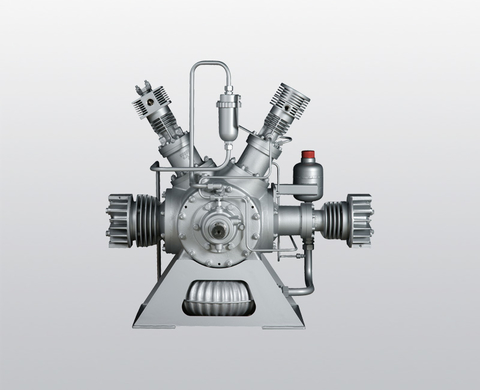

Compressor block

For compressor units with intake pressure, the BK 23 to BK 52 block series feature a pressure-tight crankcase for uniform absorption of the internal gas forces. Read more

Screw booster concept

The BAUER GIB-SP-series forms a compact, structural unit and comprises a combination of a screw compressor and a high-pressure booster. The continuous shaft allows the motor to operate the V-belt driven screw compressor and the direct-coupled booster at the same time. Read more

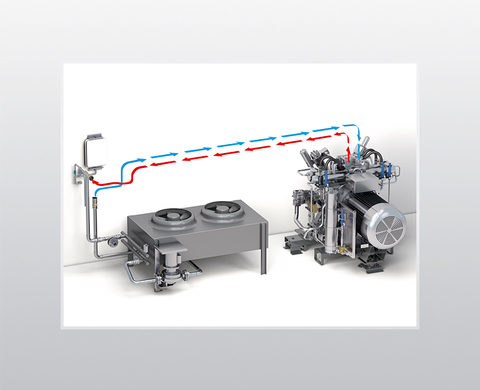

Water cooling

By using targeted water cooling between the interstage and afterstage coolers and valve heads, the system enables the majority of the heat produced to be absorbed by the cooling water. This maintenance-friendly cooling concept is suitable in particular for difficult spatial and ambient conditions where it would not be possible to use an air-cooled compressor.

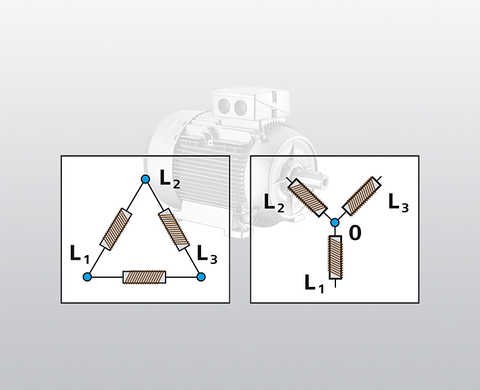

Start-up configuration

At and above motor power ratings of 75 kW and in conjunction with the B-CONTROL, a soft starter to protect the unit during starting and effectively reduce starting current is used as standard. The technical alternative is soft staring with a frequency inverter. Read more

Monitoring of pressure and temperature

This add-on module for the B-CONTROL control monitors the pressures and temperatures of all compressor stages. Read more

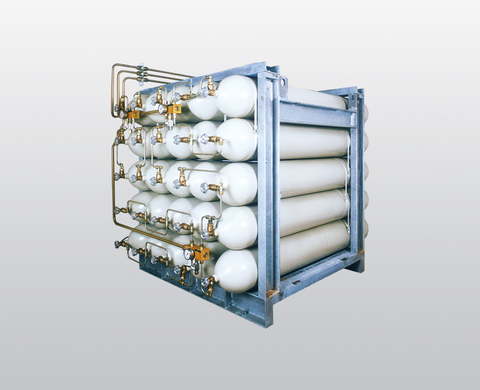

Storage systems

Modular high-pressure storage systems by BAUER KOMPRESSOREN are the ideal way to expand a compressor system. Read more

Plate heat exchanger set

The plate heat exchanger set can be used to build a dedicated enclosed compressor cooling water circuit. In open cooling systems with stream water or sea water or open cooling towers, this is essential in order to operate the compressor with cooling water of suitable quality.

Scope of delivery, basic version

Complete compressor unit ready for operation. Read more

| Type designation | Effective free air delivery ¹ | Max. operating pressure ² | Number of compressor stages | Speed approx. | Motor output | Power consumption ¹ | Net weight approx. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| l/min | m³/h | cfm | bar | psig | rpm | kW | kW | kg | lbs | ||

| GIB 26.7-SP-110 | 15000 | 900 | 530 | 110 | 1600 | 3 | 1485 | 315 | 260 | 4600 | 10200 |

| GIB 26.12-SP-365 | 10400 | 624 | 367 | 365 | 5300 | 5 | 1485 | 250 | 213 | 4400 | 9700 |

| GIB 26.12-SP-420 | 10400 | 624 | 367 | 420 | 6100 | 5 | 1485 | 250 | 220 | 4400 | 9700 |

| GIB 26.12-SP-520 | 10400 | 624 | 376 | 520 | 7540 | 5 | 1485 | 250 | 227 | 4400 | 9700 |

¹ Free air delivery according to ISO 1217, power consumption at maximum final pressure under certain conditions. Other ambient conditions result in different performance data. Direct-coupled units: Values valid for 50 Hz.

² Max. operating pressure = max. safety valve pressure setting; reduced switch-off pressure.

Downloads for water-cooled industrial compressors

The new SP Series: Maximum Capacity – Minimum Footprint

BAUER Compressors for Industry – Tailored to your requirements