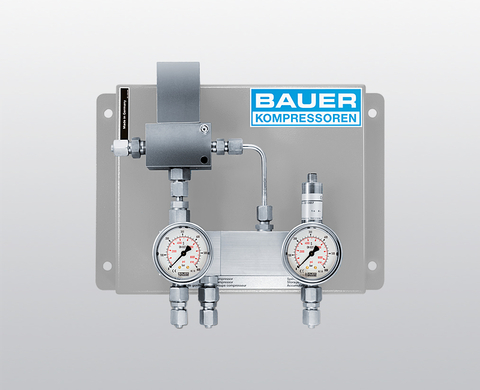

How the automatic selector unit works

Once the compressed air cylinder has been connected to the filling panel and the cylinder and filling valves have been opened, compressed air flows out of the storage system and into the compressed air cylinder. This flow continues until pressure equalisation between compressed air cylinder and storage cylinder is achieved. At this point, the automatic selector unit switches on the compressor and starts to fill the compressed air cylinder to be filled until the maximum cylinder filling pressure is reached. Once the compressed air cylinder is full, the automatic selector unit switches over again: next, the compressor refills the storage system until it switches off automatically when the maximum storage pressure is reached.

This process runs without manual intervention and is very reliable thanks to being 100% reproducible.