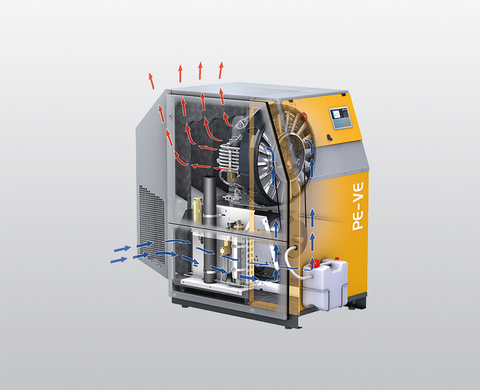

The PE-VE range – an all-rounder for the industrial sector

Compact dimensions: For installation wherever space is at a premium

Fully automatic B-CONTROL MICRO compressor control with colour display

B-DRAIN: The new automatic condensate drain is quieter and saves energy

Optional super-silent housing: for lower noise emissions

Very easy to maintain: The tension of the V-belt does not have to be adjusted

With the new PE-VE, BAUER has designed a series of system components that combines interesting features with an outstanding price-performance ratio, even in the basic version.

In combination with the numerous system options and a wide range of accessories, tailored solutions for almost all tasks in the air and nitrogen sector can be implemented.

At the heart of the system are BAUER’s compressor blocks, which have earned themselves a legendary reputation on the market for their reliability and durability. The systems technology used is designed for industrial use.

If air or nitrogen need to be compressed using intake pressure, the BAUER COMPRESSORS PE-VE series’ air-cooled booster is the ideal system solution.

All the information you need at your fingertips!

B-CONTROL MICRO compressor control

The B-CONTROL MICRO is a modern, easy-to-use compressor control with colour display for the control and reliable monitoring of all basic functions. Read more

PE-VE – the concept

The PE-VE series is a classic within the BAUER product range. Enhanced and perfected over the years, the construction has proven itself a thousand times over and stands for reliability, user-friendliness and ease of maintenance. Read more

Compressor blocks

With their outstanding surface hardness, plasma-nitrided and plateau-honed cylinders are able to achieve extremely long service lives combined with low energy consumption and reliable oil lubrication of cylinder surfaces. Read more

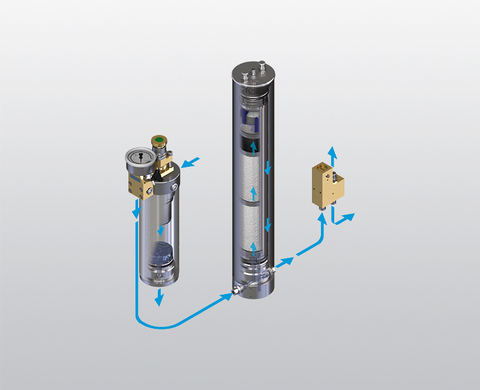

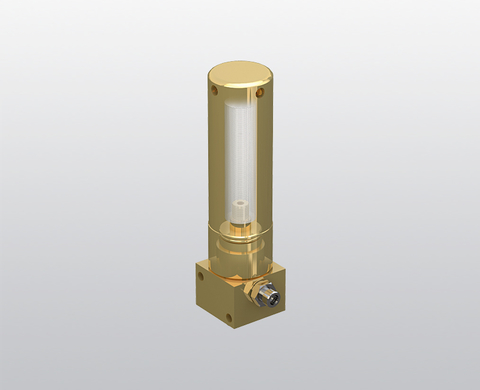

B-DRAIN automatic condensate drain

The automatic condensate drain automatically removes the condensate that forms during compression (water/oil mixture) from the intermediate separators and the final separator and collects it in a condensate vessel. Read more

AIR COOLING

Compressors in the PE-VE series are cooled directly using ambient air. The heat they generate is discharged efficiently and effectively. Read more

Drive

A low-maintenance, self-tensioning V-belt drive is used for power transmission in the PE-VE series. The integration of a motor rocker means that the tension of the V-belt does not need to be adjusted. The compressor units are fitted ex works with energy-saving three-phase motors which meet the requirements of energy efficiency class IE3.

B-APP

The B-APP allows remote access to BAUER compressors with the B-CONTROL MICRO control via the B-CLOUD. It offers useful features such as calculation tools, an integrated worldwide dealer search, news and videos about compressed air and BAUER compressors. Available in the App Store (iOS) and on Google Play (Android). Read more

B-SECURUS filter monitoring

The B-SECURUS system monitors the saturation of the filter cartridge(s) by measuring the moisture in the molecular sieve. Read more

B-KOOL III refrigeration dryer

The normal service life (capacity) of a filter cartridge can be extended many times over by additional cooling of the compressed air with the B-KOOL III refrigeration dryer. Read more

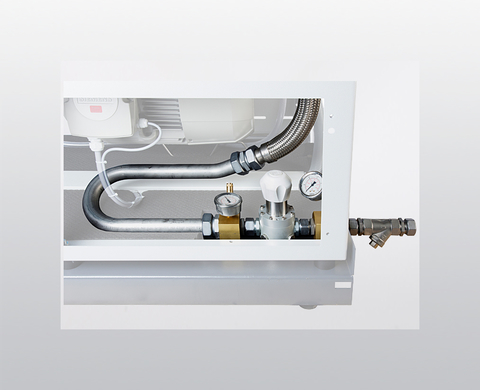

Intake pressure reduction

IIntake pressure reduction ensures that the compressor takes in the gas at the appropriate pressure. The level of intake pressure reduction is adjusted according to prevailing gas pressure and required intake pressure. Integrated safety valves and pressure monitoring effectively ensure that intake pressure does not fall below or above the permissible level.

60-litre condensate vessel

The generous 60 l condensate collection system provides a central collection point for the condensate produced during the compression process inside the compressor. Read more

Exhaust shaft

Two types of exhaust shaft are available for the installation of compressors in containers, housings or service rooms. Read more

Scope of delivery, basic version

Complete compressor unit ready for operation. Read more

| Type designation | Effective free air delivery ¹ | Intake pressure | Operating pressure ² | No. of compr. stages | Speed | Motor output | Power consumption ¹ | Net weight approx. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| l/min | m³/h | cfm | barg | bar | psig | rpm | kW | kW | kg | lbs | ||

PE 10.2-7.5-VE | ||||||||||||

| PE 10.2-7.5-VE | 290 | 17.4 | 10.2 | 2 | 365 | 5300 | 3 | 1350 | 7.5 | 5.3 | 310 | 685 |

| 385 | 23.1 | 13.6 | 3 | 6.3 | ||||||||

PE 12.2-5.5-VE | ||||||||||||

| PE 12.2-5.5-VE | 200 | 12 | 7.1 | 5 | 365 | 5300 | 2 | 1230 | 5.5 | 3.3 | 290 | 640 |

| 295 | 17.7 | 10.4 | 7 | 4.0 | ||||||||

| 390 | 23.4 | 13.8 | 9 | 4.6 | ||||||||

| 475 | 28.5 | 16.8 | 11 | 5.1 | ||||||||

PE 15.3-11-VE | ||||||||||||

| PE 15.3-11-VE | 510 | 30.6 | 18 | 7 | 365 | 5300 | 2 | 1140 | 11 | 6.6 | 350 | 770 |

| 590 | 35.4 | 20.8 | 8 | 7.1 | ||||||||

| 670 | 40.2 | 23.7 | 9 | 7.7 | ||||||||

| 750 | 45 | 26.5 | 10 | 8.2 | ||||||||

| PE 15.3-11-VE (high flow) | 660 | 39.6 | 23.3 | 7 | 365 | 5300 | 2 | 1440 | 15 | 10 | 360 | 795 |

| 760 | 45.6 | 26.8 | 8 | 10.8 | ||||||||

| 850 | 51 | 30 | 9 | 11.5 | ||||||||

| 950 | 57 | 33.5 | 10 | 12.2 | ||||||||

PE 15.41-15-VE | ||||||||||||

| PE 15.41-15-VE | 430 | 25.8 | 15.2 | 2 | 365 | 5300 | 3 | 1350 | 15 | 9.0 | 365 | 805 |

| 590 | 35.4 | 20.8 | 3 | 10.6 | ||||||||

| 750 | 45 | 26.5 | 4 | 12.1 | ||||||||

| PE15.41-15-VE (high flow) | 490 | 29.4 | 17.3 | 2 | 365 | 5300 | 3 | 1530 | 15 | 10.5 | 365 | 805 |

| 660 | 39.6 | 23.3 | 3 | 12.5 | ||||||||

| 830 | 49.8 | 29.3 | 4 | 14.5 | ||||||||

¹ Free air delivery according to ISO 1217, power consumption at maximum final pressure under certain conditions. Other ambient conditions result in different performance data. Values valid for 50 Hz.

² Max. operating pressure = max. safety valve pressure setting; reduced switch-off pressure.

| Type designation | Effective free air delivery ¹ | Intake pressure | Shut-down pressure min. | max. ² | No. of compr. stages | Speed approx. | Motor output | Power consumption ¹ | Net weight approx. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| l/min | m³/h | cfm | mbarg | bar | bar | rpm | kW | kW | kg | lbs | ||

PE-VE Booster | 25 – 50 bar | ||||||||||||

| PE12.3-5.5-VE | 610 | 37 | 21.5 | 5 | 25 | 360 | 1 | 1300 | 5.5 | 3.1 | 290 | 640 |

| 550 | 33 | 19.4 | 5 | 30 | 435 | 3.2 | ||||||

| 465 | 28 | 16.4 | 5 | 40 | 580 | 3.2 | ||||||

| 1040 | 62 | 36.7 | 7.5 | 25 | 360 | 3.7 | ||||||

| 950 | 57 | 33.5 | 7.5 | 30 | 435 | 4 | ||||||

| 800 | 48 | 28.3 | 7.5 | 40 | 580 | 4.3 | ||||||

| 700 | 42 | 24.7 | 7.5 | 50 | 725 | 4.5 | ||||||

| 1470 | 88 | 51.9 | 10 | 25 | 360 | 4 | ||||||

| 1390 | 83 | 49.1 | 10 | 30 | 435 | 4.6 | ||||||

| 1210 | 73 | 42.7 | 10 | 40 | 580 | 5.2 | ||||||

| 1080 | 65 | 38.1 | 10 | 50 | 725 | 5.4 | ||||||

¹ Free air delivery according to ISO 1217, power consumption at maximum final pressure under certain conditions. Other ambient conditions result in different performance data. Values valid for 50 Hz.

² Shut-down pressure (sensor setting).