BM-series – air-cooled, medium-pressure compressors for the compression of air

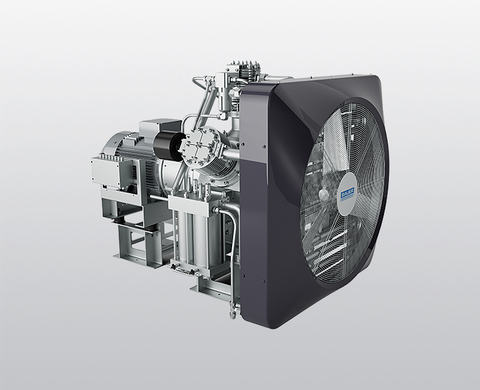

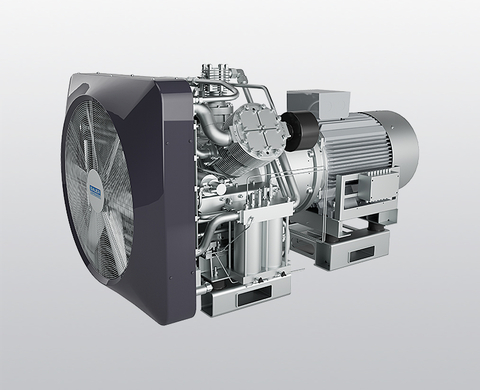

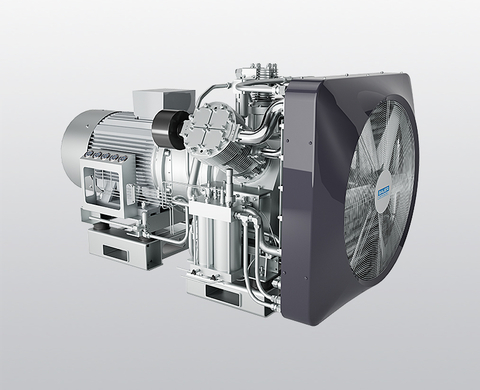

Direct-coupled BAUER medium-pressure compressors: Perfectly designed for ship installations with very high performance requirements

Low centre of gravity and inclinations of up to 30°: Ideal for offshore applications

Air-cooled design with a large cooling fan: Provides optimal cooling across all cylinders even at high ambient temperatures

Compact dimensions: The space-saving, low-maintenance and reliable solution – even for limited spaces

The BAUER BM-series offers a wide power range from 11 – 110 kW with delivery rates from 630 – 6200 l/min. The compressors are available in a 2-stage version for discharge pressures up to 30 bar or in a 3-stage version for discharge pressures up to 40 bar and 100 bar.

Outstanding quality, reliability and operational safety as well as ease of maintenance and cost efficiency make the BM-series the first choice worldwide.

Low oil consumption, long maintenance intervals and transparent maintenance kits also reduce the total cost of ownership (TCO).

Typical applications of the BM-series:

- Shipbuilding industry and shipping

- Marine

- Offshore applications

- Energy sector

- Defence industry

- Industrial applications

All the information you need at your fingertips!

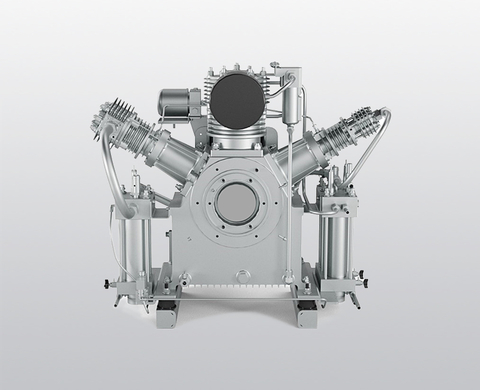

Compressor block

The compressor blocks of the BM-series have 2 or 3 compressor stages in BAUER quality. Integrated oil pump provides forced lubrication to all essential components of the compressor under the most severe operating conditions. Air-cooled design with a large cooling fan provides optimal cooling across all cylinders even at high ambient temperatures. All compression stages are protected with integrated inter-stage safety valves.

BM series – the concept

Low centre of gravity with the ability to operate at inclinations up to 30° under motion makes this an ideal product for shipboard and offshore applications. Integrated intermediate separators and an automatic condensate drain are part of the standard scope of delivery. The complete units consisting of compressor unit, motor, automatic condensate drain and control and are delivered tested and ready for operation.

B-CONTROL-C MICRO compressor control

The B-CONTROL-C MICRO is a modern, easy-to-use compressor control with colour display. In addition to the basic functions such as control of the motor and automatic condensate drain, it has functions such as monitoring of pressure and temperature, recording of load changes in the final separator and display of operating hours.

B-CONTROL-C II

The compressor control B-CONTROL-C II is a powerful control with 4.3" touch screen colour display. In addition to the basic functions such as motor and automatic condensate control, it enables monitoring of pressure and temperature, recording of load changes in the final separator, maintenance management, direction of rotation monitoring and operating hours display. Additional features such as logbook and Modbus interface as well as a multitude of expansion and customisation options complete the scope of performance.

Treatment systems

BAUER treatment systems for highly compressed air and gases reduce content such as moisture, oil and particles to a permissible level. Read more

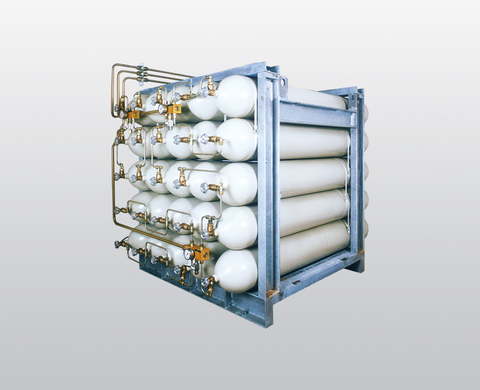

Storage systems

Modular high-pressure storage systems by BAUER KOMPRESSOREN are the ideal way to expand a compressor system. Read more

BM-series medium-pressure compressors, 630 – 6200 l/min, 30 – 100 bar

| Type designation | Effective free air delivery ¹ | Frequency | Shut-down pressure ² | Number of compressor stages | Speed approx. | Motor output | Net weight approx. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| l/min | m³/h | cfm | Hz | bar | psig | rpm | kW | kg | lbs | ||

BM-series 30 bar | |||||||||||

| BM6.1/30-11 | 770 | 46.2 | 27.2 | 50 | 30 | 435 | 2 | 1470 | 11 | 415 | 915 |

| BM10.1/30-15 | 1000 | 60 | 35.3 | 50 | 30 | 435 | 2 | 1480 | 15 | 430 | 950 |

BM-series 40 bar | |||||||||||

| BM6.1/40-11 | 660 | 39.6 | 23.3 | 50 | 40 | 580 | 3 | 1470 | 11 | 425 | 935 |

| BM10.1/40-15 | 1080 | 64.8 | 38.1 | 50 | 40 | 580 | 3 | 1480 | 15 | 440 | 970 |

| BM20.1/40-30 | 2210 | 132.6 | 78 | 50 | 40 | 580 | 3 | 1475 | 30 | 960 | 2115 |

| BM30.1/40-45 | 3110 | 186.6 | 110 | 50 | 40 | 580 | 3 | 1480 | 45 | 1075 | 2370 |

| BM60.1/40-90 | 6200 | 372 | 219 | 50 | 40 | 580 | 3 | 1480 | 90 | 2040 | 4495 |

BM-series 100 bar | |||||||||||

| BM6.1/100-15 | 630 | 37.8 | 22.2 | 50 | 100 | 1450 | 3 | 1470 | 15 | 435 | 960 |

| BM10.1/100-18.5 | 1060 | 63.6 | 37.4 | 50 | 100 | 1450 | 3 | 1485 | 18.5 | 475 | 1045 |

| BM20.1/100-37 | 2180 | 130.8 | 77 | 50 | 100 | 1450 | 3 | 1485 | 37 | 1010 | 2225 |

| BM30.1/100-55 | 3080 | 184.8 | 109 | 50 | 100 | 1450 | 3 | 1485 | 55 | 1150 | 2535 |

| BM60.1/100-110 | 6150 | 369 | 217 | 50 | 100 | 1450 | 3 | 1485 | 110 | 2390 | 5270 |

| Type designation | Effective free air delivery ¹ | Frequency | Shut-down pressure ² | Number of compressor stages | Speed approx. | Motor output | Net weight approx. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| l/min | m³/h | cfm | Hz | bar | psig | rpm | kW | kg | lbs | ||

BM-series 30 bar | |||||||||||

| BM6.1/30-15 | 930 | 55.8 | 32.8 | 60 | 30 | 435 | 2 | 1775 | 15 | 425 | 935 |

| BM10.1/30-18.5 | 1150 | 69 | 40.6 | 60 | 30 | 435 | 2 | 1775 | 18.5 | 470 | 1035 |

BM-series 40 bar | |||||||||||

| BM6.1/40-15 | 800 | 48 | 28.2 | 60 | 40 | 508 | 3 | 1770 | 15 | 435 | 960 |

| BM10.1/40-18.5 | 1300 | 78 | 45.9 | 60 | 40 | 508 | 3 | 1780 | 18.5 | 475 | 1045 |

| BM20.1/40-37 | 2670 | 160.2 | 94.3 | 60 | 40 | 580 | 3 | 1780 | 37 | 980 | 2160 |

| BM30.1/40-55 | 3750 | 225 | 132 | 60 | 40 | 580 | 3 | 1780 | 55 | 1150 | 2535 |

| BM60.1/40-75 | 4960 | 297.6 | 175 | 60 | 40 | 580 | 3 | 1185 | 75 | 2350 | 5180 |

BM-series 100 bar | |||||||||||

| BM6.1/100-15 | 760 | 45.6 | 26.8 | 60 | 100 | 1450 | 3 | 1775 | 15 | 435 | 960 |

| BM10.1/100-22 | 1280 | 76.8 | 45.2 | 60 | 100 | 1450 | 3 | 1780 | 22 | 490 | 1080 |

| BM20.1/100-45 | 2620 | 157.2 | 92.5 | 60 | 100 | 1450 | 3 | 1780 | 45 | 1040 | 2295 |

| BM30.1/100-75 | 3690 | 221.4 | 130 | 60 | 100 | 1450 | 3 | 1780 | 75 | 1300 | 2865 |

| BM60.1/80-90 | 4910 | 294.6 | 173 | 60 | 80 | 1160 | 3 | 1185 | 90 | 2460 | 5425 |

¹ Free air delivery according to ISO 1217, power consumption at maximum final pressure under certain conditions. Other ambient conditions result in different performance data.

² Max. Shut-off pressure. Set pressure safety valve 10% higher.