KAP-DAH – The high-performance BAUER breathing air compressors for standalone use in remote locations

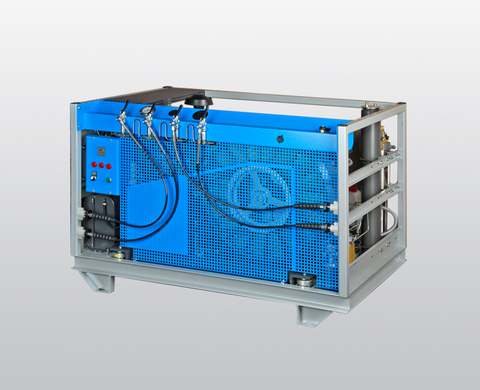

Ideal for use in standalone applications: Featuring a very low-maintenance diesel engine

Electronic compressor control (KAP-DAH): For reliable control of the most important unit parameters

Little space required: Thanks to compact horizontal design

Long service life, high degree of modularity: Tailored to meet your needs

With a low centre of gravity and robust, low-maintenance diesel drive, the horizontal compressors in the KAP-DAH series are able to meet the most exacting of requirements for reliable and autonomous continuous operation in remote locations.

All coolers, filters, valves and cables are made from rust-free materials.

Designed for the harshest of outdoor climates and absolutely reliable at high outdoor temperatures.

The unit has been designed without compromise, so ease of access for maintenance work comes as standard.

All the information you need at your fingertips!

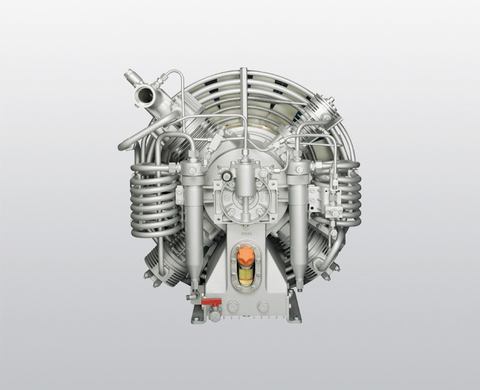

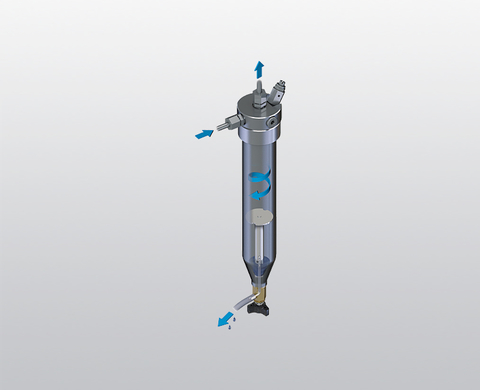

IK 15.1/150/180 compressor blocks

The compressor stages, which are located on sides of the compressor blocks, are the key to optimum smooth running and high efficiency. The free-standing cylinders are easy to access and maintain. Read more

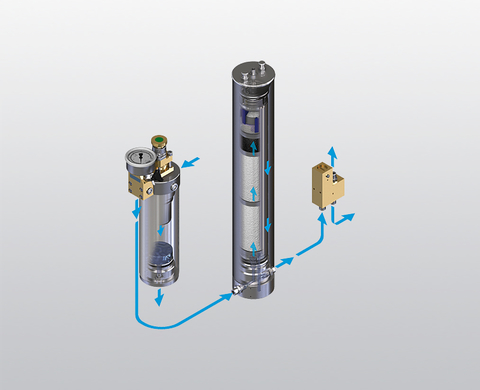

P 61 or P 81 filter system

When used in conjunction with original BAUER filter cartridges, the P 61 or P 81 filter system with additional oil and water separator and pressure retention check valve can be relied upon for breathing air treatment conforming to DIN EN 12021¹. A type-tested and sealed final pressure safety valve enables particularly high levels of operational safety to be achieved. 2400 m³ (P 61) or 5200 m³ (P 81) of air can be treated.

¹ If the units are maintained and installed correctly as described in the user manual and subject to the BAUER AERO-GUARD being used if CO2 concentration in the intake air exceeds prescribed standard values.

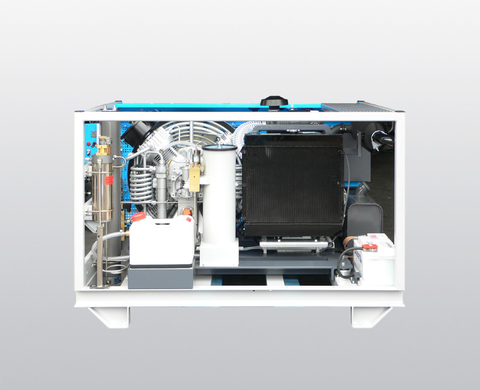

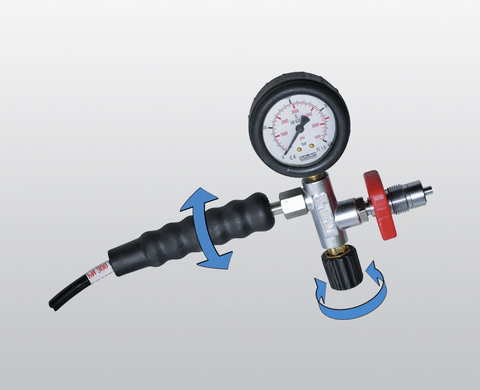

Compressor control (KAP-DAH)

The electronic control with additional monitoring electronics switches the compressor off automatically when the final pressure is reached in the system, measures operating hours and oil pressure, and displays the current operating status. The battery charge status can also be read off from the control box.

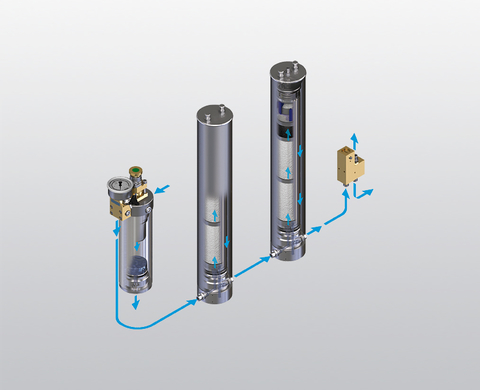

P 81 Purification system

When used in conjunction with original BAUER filter cartridges, the P 81 filter system with additional oil and water separator and pressure retention check valve can be relied upon for breathing air treatment conforming to DIN EN 12021:2014¹. A type-tested and sealed final pressure safety valve enables particularly high levels of operational safety to be achieved. 5,200 m³ of air can be treated.

¹ If the units are maintained and installed correctly as described in the user manual and subject to the BAUER AERO-GUARD being used if CO2 concentration in the intake air exceeds prescribed standard values.

Additional intermediate separator after the first stage

In the case of operation in locations where air humidity is high (tropical regions, for example), we recommend installing a separator downstream of the first compressor stage. This can extend the service life of the unit and reduce maintenance costs.

Paint finish/Special paint finish

All frame parts of BAUER compressors are finished with a sophisticated powder coating. Read more

AERO-GUARD

Using the AERO-GUARD reduces the CO2 content of the breathing air to approximately one-third of the intake value. The constantly increasing levels of CO2 concentration in the air resulting from unfavourable environmental influences are making it more and more difficult for the operators of filling stations to be sure of achieving compliance with legally binding maximum limits for CO2. With AERO-GUARD the operator is always on the safe side! Read more

Scope of delivery, basic version

Complete compressor unit ready for operation. Read more

| Type designation | Charging rate ¹ | Max. operating pressure | Speed approx. | Motor output | Filter system | Net weight | Dimensions L × W × H | ||

|---|---|---|---|---|---|---|---|---|---|

| l/min | cfm | bar | rpm | kW | kg | lbs | cm | ||

| KAP 15.1-14-DAH | 450 | 16 | 330 | 1320 | 14 | P 61 | 500 | 1100 | 146.5 × 100 × 97 |

| KAP 150-16-DAH | 540 | 19 | 330 | 1230 | 16 | P 61 | 500 | 1100 | 146.5 × 100 × 97 |

| KAP 180-18-DAH | 680 | 24 | 330 | 1400 | 18 | P 81 | 516 | 1135 | 146.5 × 100 × 97 |

¹ Measured with cylinder filling (10 l) from 0 to 200 bar, ±5%

Downloads for the KAP-LINE, compressor and compressor accessories

BAUER PREMIUM LINE – Compressors for sports & safety applications

Product overview – Compressor systems & accessories for medium and pressure