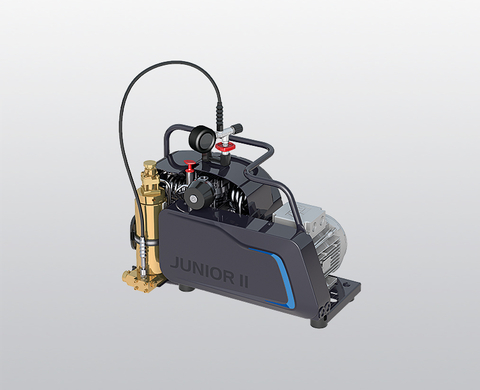

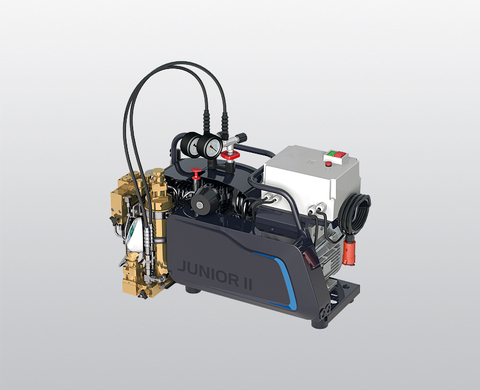

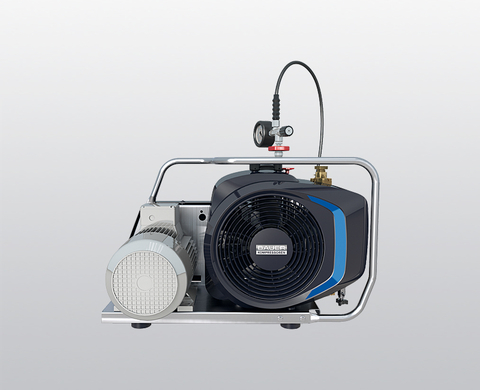

JUNIOR II – The compact classic in a new design

The world's best seller: With more than 100,000 units around the globe

The most compact mobile compressor from BAUER in a trendy new design and with improved technology

Optimised cooling and a new belt guard mean longer filter service life

Classy and easy to transport: Lightweight and modern design

Extensive range of applications

Reliable, durable and extremely versatile in its applications, the JUNIOR II offers many convincing aspects which have made it a global classic with more than 100,000 units sold. Now with a new, more sophisticated and up-to-date design!

Thanks to its very small dimensions and improved technology, the compressor is ideally suited for shipping, as a diving compressor, in respiratory applications, and as a compressor for paintball and sport shooting. The lightweight JUNIOR II can be carried easily by a single person and will fit in any vehicle boot.

So if you need high-purity, safe breathing air for a mobile application and at the same time put a high value on quality and reliability, the JUNIOR II is ideal for you.

All the information you need at your fingertips!

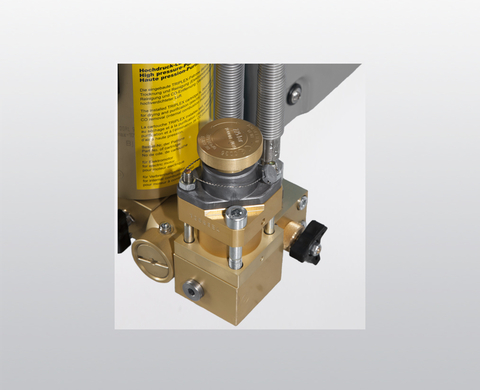

JUNIOR II compressor block

The high-pressure compressor block is the beating heart of the JUNIOR. Epitomising reliability and having proven its worth in practice for decades, more than 100,000 units have been sold the world over. Read more

P 21 filter system

When used in conjunction with original BAUER filter cartridges, the P 21 filter system with integrated oil and water separator and pressure retention check valve can be relied upon for breathing air treatment conforming to DIN EN 12021¹. A type-tested and sealed final pressure safety valve enables particularly high levels of operational safety to be achieved. 140 m³ of air can be treated.

¹ If the units are maintained and installed correctly as described in the operating instructions or user manual and if the concentration of CO2 in the intake air does not exceed the values specified in the applicable standard for breathing air.

B-TIMER filter cartridge monitoring

The operating hours and the current level of cartridge saturation are displayed on the unique B-TIMER mini-computer. Read more

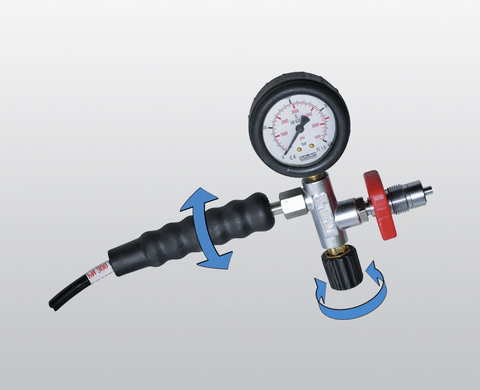

Filling device

The filling device comprises a flexible "UNIMAM" high-pressure filling hose and filling valve complete with final pressure gauge. The final pressure gauge makes it easy to read off the filling pressure. It is protected against damage by a durable rubber jacket.

Filling hose

High-quality UNIMAM high-pressure filling hoses made from food-safe and long-life hose material make for flexible and safe handling. Swivel hose connections enable the filling valve to be connected to the breathing air cylinder quickly, easily and safely.

Switch-over device PN 300/200 bar

For easy switching between filling pressures of 200 and 300 bar. Read more

Automatic condensate drain complete with automatic switch-off when the final pressure is reached

The automatic condensate drain removes water from the intermediate separator and the final separator automatically during both operation and shutdown. This makes things infinitely more convenient for the operator, as there is no longer any need for the time-consuming process of draining condensate manually at regular intervals. Another benefit is that the compressor is switched off automatically when the final pressure is reached.

At BAUER, safety always comes first: all of our models are equipped with an electric drive conforming to DIN EN 60204 for full CE conformity with a miniature control complete with control transformer.

Trolley

The trolley for the COMPACT-LINE units is designed for the simple and safe transportation of your compressor across any terrain. This is ensured by the large pneumatic tyres and the stable manner in which the compressor is secured.

For maximum flexibility, you can either leave the compressor on the trolley or lift it down to operate it. Turning a handle on the trolley allows you to secure your JUNIOR or OCEANUS in place and lift it back down again.

The length of the handle can also be adjusted to make handling the trolley particularly easy. The handle can also simply be detached to allow for convenient transportation of the trolley by car.

Paint finish/Special paint finish

All frame parts of BAUER compressors are finished with a sophisticated powder coating. Read more

Scope of delivery, basic version

Complete compressor unit ready for operation. Read more

| Type designation | Charging rate ¹ | Drive | Net weight | Dimensions L × W × H | |

|---|---|---|---|---|---|

| l/min | Motor | kW | approx. kg | cm | |

| JUNIOR II-B | 100 | Petrol engine | 4.2 | 45 | 79 × 37 × 44 |

| JUNIOR II-E | 100 | Three-phase motor, 400 V, 50 Hz ² | 2.2 | 49 | 69 × 39 × 44 |

| JUNIOR II-W | 100 | Alternating current motor 230 V, 50 Hz ² | 2.2 | 52 | 69 × 40 × 44 |

¹ Measured with cylinder filling from 0 to 200 bar, ±5%

² Option of different voltage/frequency available

Downloads for the COMPACT-LINE compressors and compressor accessories

COMPACT LINE – Compressors for sports & safety applications

BAUER PREMIUM LINE – Compressors for sports & safety applications