The automatic selector unit – for simultaneous filling of compressed air cylinders from storage system and compressor

The automatic selector unit enables compressed air cylinders (cylinders) to be filled quickly at the filling panel from a single storage system (buffer) and via the compressor simultaneously. It also supports the subsequent automatic refilling of the storage system by the compressor.

The storage bottle connected to the filling panel takes priority for filling, i.e. the storage system and the compressor always start by filling the breathing air cylinders at the filling panel.

Once the storage bottle has been filled, the automatic selector unit ensures that the storage system is then filled by the compressor.

When the maximum filling pressure is reached in the storage system, the compressor shuts down again. As soon as the next empty storage bottle is connected to the filling panel, the automatic cycle starts again from the beginning.

All the information you need at your fingertips!

The automatic selector unit performs 3 important functions

- Advance filling of the compressed air cylinders from the storage system by means of compressed air overflow up to the pressure equalisation point.

- Filling of the connected compressed air cylinder directly by the compressor until the cylinder filling pressure is reached.

- Topping up of the storage system until the maximum storage pressure is reached.

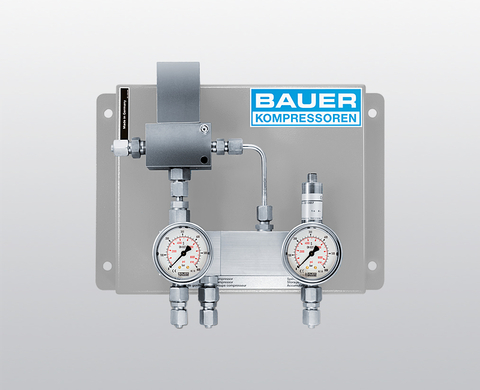

Scope of delivery

- Paint-finished steel baseplate for wall mounting

- Pressure retention valve

- Check valve

- Pressure switch or pressure sensor, depending on the connected compressor control

- Pressure gauge

Technical data

- Transition: DN4

- Operating pressure: PN350 bar / 420 bar

- Adjustment range: Pressure relief valve / pressure retention valve: 100 - 350 bar

- Dimensions: W x H x D: 400 x 250 x 150 mm

Connections

- Input: G 3/8, connection for either Ø 8 mm or Ø 10 mm pipe

- Output: Ø 8 or Ø 10 mm