BAUER Nitrox compressors – compressing nitrox safely!

TÜV certified safety: Type examination of the compressor by TÜV Süd.

Nitrox optimised compressor: Compressor block optimised for increased oxygen content and temperature monitoring for your added safety

Whether open or sound-insulated, mobile or stationary – the BAUER Nitrox series of units contains the right model for almost every application. For faster response times, all BAUER Nitrox compressors are equipped with temperature sensors in the final separator and for the cooling air, which monitor compliance with the specified operating temperature online. All components and oils used are also designed for use with an increased oxygen content.

Extensive tests are required due to the high safety standards governing the compression of gases enriched with oxygen. All materials used in the unit that come into direct contact with the gas must demonstrate that they are harmless under the strictest TÜV criteria and defined test procedures. These tests ensure that the nitrox mixture generated by the oxygen membrane with a maximum oxygen content of 40% can be compressed safely in the downstream high-pressure compressor.

BAUER KOMPRESSOREN only uses 4-stage compressor blocks for the compression of nitrox. This ensures that the heat produced during the process of compression is distributed across all four stages, promoting effective cooling.

The free-standing cylinders are easy to access and maintain. Furthermore, they are ideally positioned in the cooling air flow.

To increase safety, online temperature monitoring in the final separator and the cooling air is made possible. If the maximum permissible temperature specified by the TÜV is exceeded, the unit shuts down automatically and the system is ventilated.

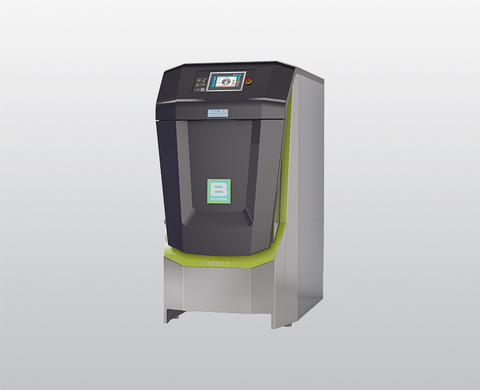

BAUER Nitrox compressors MINI-VERTICUS-OX and VERTICUS-OX

(MINI-)VERTICUS Nitrox – The compressors for high performance requirements in continuous operation for the compression of nitrox and breathing air. Equipped with B-CONTROL MICRO compressor control and temperature monitoring of the cooling air as well as in the final separator.

Read more