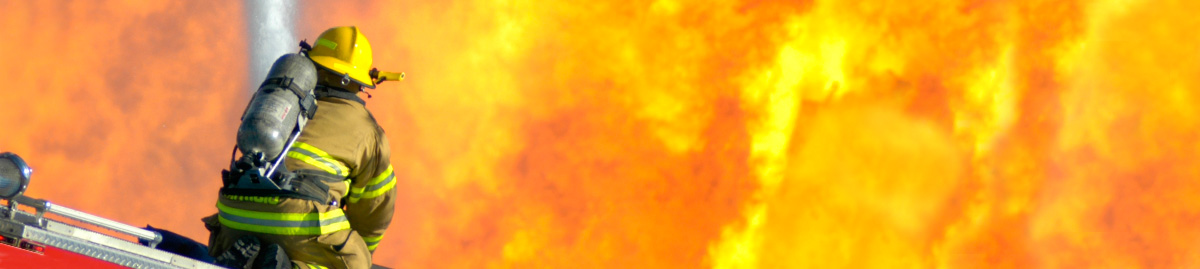

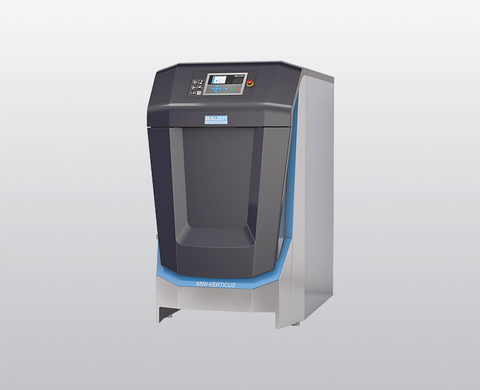

MINI-VERTICUS and VERTICUS Nitrox – The compressors for high performance requirements for the compression of nitrox and breathing air

Type examination for operation with up to 40% oxygen content

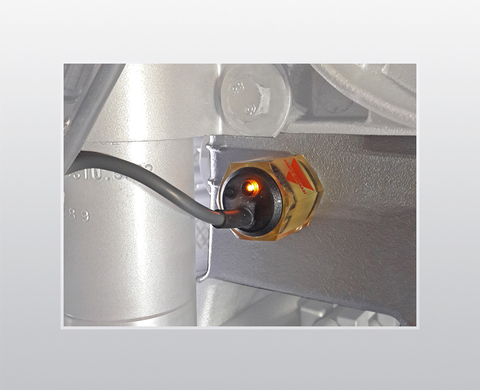

Temperature monitoring in the final separator and the cooling air

Now significantly quieter: thanks to the new anti-vibration frame and noise-optimised Super Silent housing

Long service life, high degree of modularity: Tailored to meet your needs

The MINI-VERTICUS and VERTICUS series has been developed and built specifically to meet high performance requirements in continuous operation in professional applications.

The new MINI-VERTICUS and VERTICUS combine the legendary BAUER compressor blocks with improved components and ultra-modern design! During the redesign, the focus was on ergonomics, making operation as easy as possible, reducing noise and boosting efficiency.

All control elements that are important for everyday operation are ergonomically arranged and easily accessible from the front. A new condensate vessel integrated into the housing with 40 % more capacity. The compressor control monitors the fill level and informs the operator in good time if the condensate needs to be emptied.

The nitrox compressors are available for the compression of nitrox with an oxygen content of up to 40% and for a maximum operating pressure of 300 bar.

All the information you need at your fingertips!

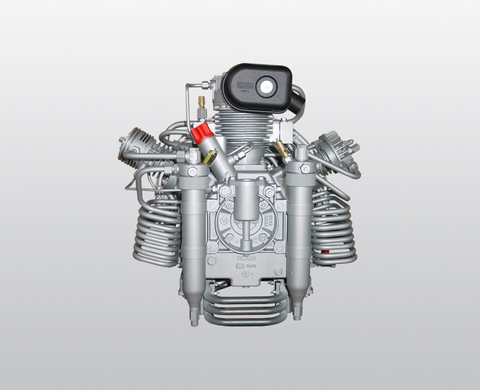

IK 12.14 compressor block

The BAUER IK 12.14 compressor block is used for both breathing air and industrial units. Its durability, reliability and high-quality design provide the basis for fault-free operation of the compressor. Read more

IK 15.1 compressor block

The compressor stages, which are located on sides of the compressor blocks, are the key to optimum smooth running and high efficiency. The free-standing cylinders are easy to access and maintain. Read more

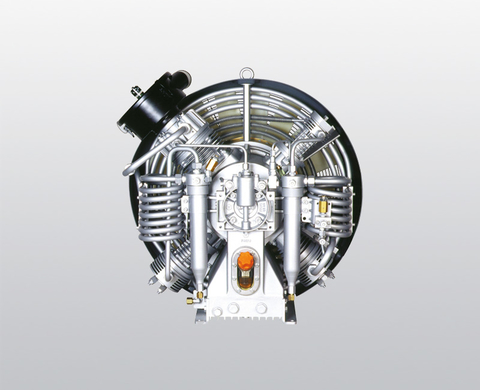

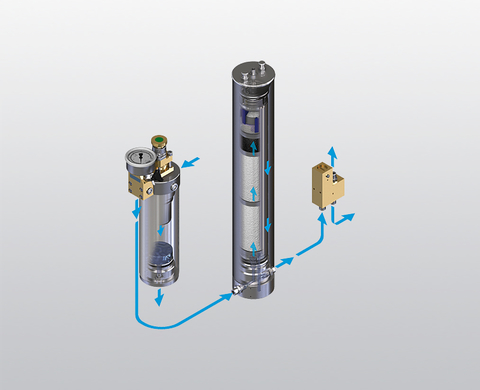

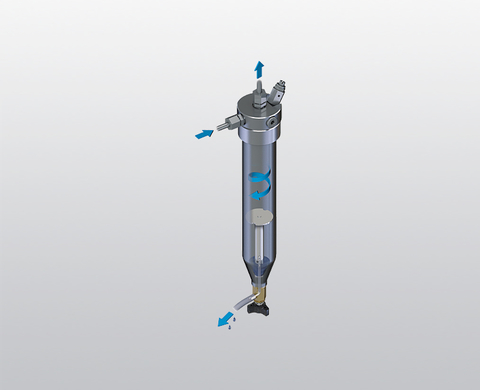

P 41 Purification system

When used in conjunction with original BAUER filter cartridges, the P 41 filter system with additional oil and water separator and pressure retention check valve can be relied upon for breathing air treatment conforming to DIN EN 12021:2014¹. A type-tested and sealed final pressure safety valve enables particularly high levels of operational safety to be achieved. 1550 m³ of air can be treated.

¹ If the units are maintained and installed correctly as described in the user manual and subject to the BAUER AERO-GUARD being used if CO2 concentration in the intake air exceeds prescribed standard values.

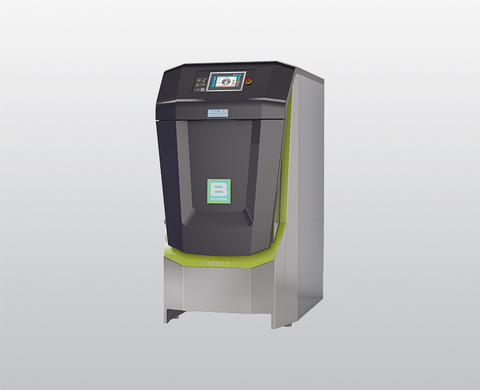

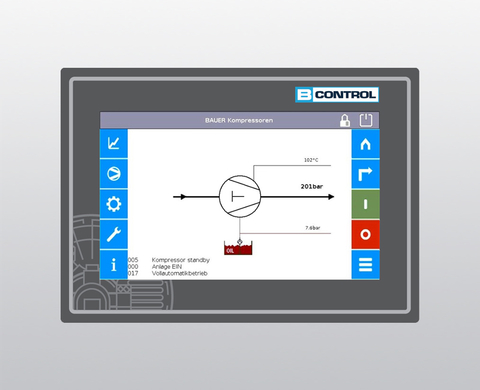

B-CONTROL MICRO compressor control

The B-CONTROL MICRO is a modern, easy-to-use compressor control with colour display for the control and reliable monitoring of all basic functions. Read more

Temperature monitoring in the final separator and the cooling air

For your safety, all BAUER B-NITROX compressors are equipped with temperature sensors for monitoring the cooling air and in the final separator. Here, compliance with the specified operating temperature is reliably monitored.

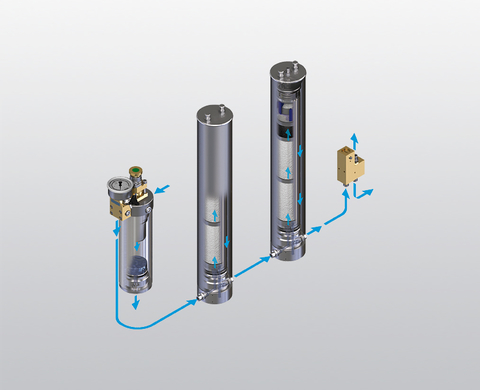

B-DRAIN automatic condensate drain

The automatic condensate drain automatically removes the condensate that forms during compression (water/oil mixture) from the intermediate separators and the final separator and collects it in a condensate vessel. Read more

Connection for external intake system

When filling breathing air cylinders, the quality of the compressed air is dependent on the quality of the ambient air intake. Clean fresh air must be taken in from an external source in particular if there is a risk of exhaust gases (CO) and exhaust air from other units. A connection for an external suction line has been provided for this purpose.

Super Silent version

Super Silent housing reduces the noise level of the compressor unit and makes the unit compatible for operation in working environments where noise is a key concern. For units in the (MINI-) VERTICUS series, Super Silent sound insulation can be retrofitted on request.

B-CONTROL III

B-CONTROL III is BAUER's premium control system for demanding applications. B-CONTROL III can be flexibly adapted to your individual requirements and, if necessary, expanded to control complete system processes. Read more

P 61 Purification system

When used in conjunction with original BAUER filter cartridges, the P 61 purification system with additional oil and water separator and pressure retention check valve can be relied upon for breathing air treatment conforming to DIN EN 12021:2014¹. A type-tested and sealed final pressure safety valve enables particularly high levels of operational safety to be achieved. 2400 m³ of air can be treated.

¹ If the units are maintained and installed correctly as described in the user manual and subject to the BAUER AERO-GUARD being used if CO2 concentration in the intake air exceeds prescribed standard values.

P 81 Purification system

When used in conjunction with original BAUER filter cartridges, the P 81 filter system with additional oil and water separator and pressure retention check valve can be relied upon for breathing air treatment conforming to DIN EN 12021:2014¹. A type-tested and sealed final pressure safety valve enables particularly high levels of operational safety to be achieved. 5,200 m³ of air can be treated.

¹ If the units are maintained and installed correctly as described in the user manual and subject to the BAUER AERO-GUARD being used if CO2 concentration in the intake air exceeds prescribed standard values.

B-APP

The B-APP allows remote access to BAUER compressors with the B-CONTROL MICRO control via the B-CLOUD. It offers useful features such as calculation tools, an integrated worldwide dealer search, news and videos about compressed air and BAUER compressors. Available in the App Store (iOS) and on Google Play (Android). Read more

Integrated gas measurement system B-DETECTION PLUS i

As an option, the B-DETECTION PLUS i gas measurement system can be integrated into the compressor. This permits the monitoring of all gases required by DIN EN 12021:2014. Thanks to the option for discharge to the outside in the event of short-term contamination and the shut-down of the compressor in the event of extended overruns of the limit values, observance of DIN EN 12021:2014 can be ensured at all times1.

1 Measurement of humidity and total oil value (VOC) as option. Total oil measurement based only on volatile organic compounds (VOCs). Sensor calibration based on isobutene.

B-SECURUS filter monitoring

The B-SECURUS system monitors the saturation of the filter cartridge(s) by measuring the moisture in the molecular sieve. Read more

Monitoring the intermediate pressures

This monitoring system is recommended for continuous operation and fully automated operation, as well as for compressor units that do not receive regular attention from specialist personnel. Monitoring tracks the minimum value of stage 1 (intermediate pressure only) and the maximum value of all compressor stages. The compressor unit shuts off if the values monitored fall below or exceed the permissible limit values. The actual value is displayed by the B-CONTROL II compressor control unit.

Oil level monitoring

Optional oil level monitoring system for safely switching off the compressor unit when the oil level is low.

If the oil level reaches the minimum mark, this is displayed on the control and the compressor is switched off automatically for safety reasons. This option is particularly recommended for compressor units in continuous operation.

Intermediate pressure gauge kit

The intermediate pressure gauges show the operating pressure of the individual compressor stages. This information about the pressure is used to check the corresponding stage valves (inlet and outlet) for leaks so that potential faults can be detected quickly. The intermediate pressure gauges are installed inside the compressor housing.

First stage separator

The installation of a separator after the first compressor stage is recommended for units operating in conditions where the moisture content of the ambient air is high (in tropical regions and for the effective compression of gases with a high moisture content. Read more

Exhaust shaft

Two types of exhaust shaft are available for the installation of compressors in containers, housings or service rooms. Read more

Exhaust shaft with ventilation damper control

The exhaust shaft with ventilation damper control provides the means via which the exhaust air is discharged into the surrounding room or outdoors under controlled conditions and dependent on temperature. A temperature sensor measures the temperature in the room and controls the position of the ventilation dampers for optimised operation (only possible in conjunction with a Super-Silent housing).

Paint finish/Special paint finish

All frame parts of BAUER compressors are finished with a sophisticated powder coating. Read more

AERO-GUARD

Using the AERO-GUARD reduces the CO2 content of the breathing air to approximately one-third of the intake value. The constantly increasing levels of CO2 concentration in the air resulting from unfavourable environmental influences are making it more and more difficult for the operators of filling stations to be sure of achieving compliance with legally binding maximum limits for CO2. With AERO-GUARD the operator is always on the safe side! Read more

60 l condensate collection system

This convenient system provides a central collection point for the condensate (oil and water mixture) produced during the compression process inside the compressor. The condensate tank features an integrated float switch which can be relied upon to monitor the level of condensate in the tank and provides protection against overfilling. A combined silencer and filter unit prevents pollution caused by noise or odour.

Scope of delivery, basic version

Complete compressor unit ready for operation. Read more

| Type designation | Charging rate ¹ | No. of compr. stages | Speed approx. | Motor output | Purification system | Net weight | Dimensions L × W × H ² | ||

|---|---|---|---|---|---|---|---|---|---|

| l/min | m³/h | cfm | rpm | kW | kg | cm | |||

| MV 260-OX | 260 | 15.6 | 9.2 | 4 | 1185 | 5.5 | P 41 | 349 | 120 × 79 × 138 |

| MV 320-OX | 320 | 19.2 | 11.5 | 4 | 1450 | 7.5 | P 41 | 350 | 120 × 79 × 138 |

| V 450-OX | 450 | 25.2 | 16 | 4 | 1320 | 11 | P 61 | 402 | 120 × 79 × 153 |

¹ Measured with cylinder filling from 0 to 200 bar (0 to 3000 psi), ±5%

² Dimensions for Super-Silent version: MINI-VERTICUS: 136 × 81 × 138 cm, VERTICUS: 154 × 81 × 153 cm

Downloads for the BAUER Nitrox compressors MINI-VERTICUS-OX & VERTICUS-OX

B-NITROX Systems – The safe and secure solution for producing and compressing nitrox